Understanding the Basics of Cost Accounting unveils the crucial role of cost analysis in business success. This exploration delves into the core principles, demonstrating how businesses utilize cost data for informed decision-making, from budgeting and pricing to evaluating operational efficiency. We will examine various costing methods, analyze cost behavior, and explore tools like break-even analysis to optimize profitability.

This guide provides a foundational understanding of cost accounting principles, covering key concepts such as cost classification, costing methods (job-order and process costing), cost-volume-profit analysis, budgeting, cost control, and standard costing. Through practical examples and clear explanations, you will gain the essential knowledge to navigate the complexities of cost management within any business environment.

Introduction to Cost Accounting: Understanding The Basics Of Cost Accounting

Cost accounting is a vital business function providing crucial insights into a company’s operational efficiency and profitability. It goes beyond simply tracking expenses; it analyzes costs to inform strategic decision-making, improve processes, and ultimately enhance the bottom line. Understanding cost accounting principles is essential for anyone involved in managing a business, from small startups to large corporations.

Cost accounting is a specialized branch of accounting that focuses on the recording, classifying, summarizing, analyzing, interpreting, and presenting of costs. Its key objectives are to determine the cost of products or services, control costs, and provide management with information for planning, decision-making, and performance evaluation. Accurate cost information enables informed pricing strategies, efficient resource allocation, and the identification of areas for cost reduction.

Real-World Applications of Cost Accounting

Businesses utilize cost accounting in diverse ways to gain a competitive edge. Here are three examples:

A manufacturing company uses cost accounting to track the direct materials, direct labor, and manufacturing overhead costs associated with producing each unit of its product. This detailed cost breakdown allows them to determine the profitability of each product line and identify areas for cost reduction, such as negotiating better prices with suppliers or improving production efficiency.

A service-based company, such as a consulting firm, uses cost accounting to allocate overhead costs (rent, utilities, administrative salaries) to individual projects. This enables the firm to accurately price its services and ensure that each project is profitable. They might use activity-based costing to assign overhead costs more accurately than traditional methods.

A retail business uses cost accounting to analyze the cost of goods sold and determine the markup required to achieve a desired profit margin. They might track costs associated with inventory management, such as storage and transportation, to optimize their supply chain and minimize expenses.

Comparison of Financial Accounting and Cost Accounting, Understanding the Basics of Cost Accounting

The following table highlights the key differences between financial accounting and cost accounting:

| Feature | Financial Accounting | Cost Accounting |

|---|---|---|

| Purpose | To prepare financial statements for external users (investors, creditors, government). | To provide cost information for internal management decision-making. |

| Users | External stakeholders (investors, creditors, regulatory bodies). | Internal management (managers, executives). |

| Information Reported | Financial statements (balance sheet, income statement, cash flow statement). | Cost reports, budgets, performance analyses. Information can include direct costs, indirect costs, cost of goods sold, and various cost allocation methods. |

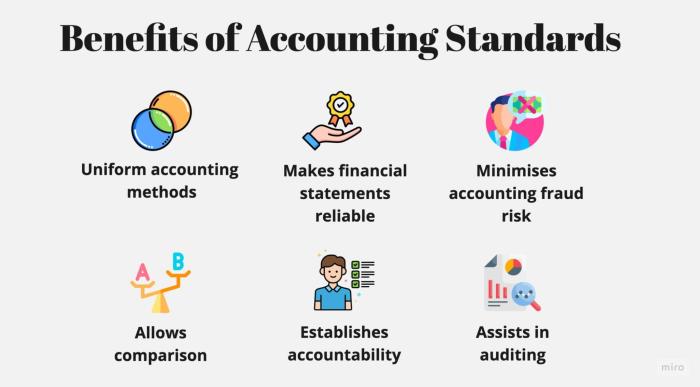

Cost Classification

Understanding how to classify costs is fundamental to effective cost accounting. Different classification methods provide valuable insights for managerial decision-making, performance evaluation, and cost control. This section explores various methods of cost classification, highlighting their significance in business operations.

Cost Classification Methods

Costs can be categorized in several ways, depending on the purpose of the analysis. Three common methods are classification by behavior (how costs react to changes in activity levels), classification by function (the purpose the cost serves within the business), and classification by traceability (whether the cost can be directly linked to a specific product or service). Each method offers a unique perspective on cost structure and behavior.

Cost Behavior

Cost behavior refers to how costs change in response to changes in activity levels. The three primary categories are fixed, variable, and mixed costs.

Fixed costs remain constant regardless of the volume of production or sales within a relevant range. Examples include rent, salaries of administrative staff, and insurance premiums. These costs remain the same even if production increases or decreases, at least within a certain range of activity.

Variable costs change directly and proportionally with changes in activity levels. Examples include direct materials, direct labor (in some cases), and sales commissions. As production increases, variable costs increase, and vice versa.

Mixed costs, also known as semi-variable costs, contain both fixed and variable components. For example, a utility bill might have a fixed monthly charge plus a variable charge based on consumption. Analyzing the fixed and variable components of mixed costs often involves techniques like the high-low method or regression analysis.

Direct and Indirect Costs

Direct costs are directly traceable to a specific product, service, or project. Direct materials and direct labor are prime examples. Direct materials are the raw materials that become part of the finished product (e.g., wood for furniture, fabric for clothing). Direct labor is the cost of labor directly involved in manufacturing or producing the product or service (e.g., wages of assembly line workers).

Indirect costs, also known as overhead costs, cannot be easily or economically traced to a specific product or service. They support the production process but are not directly part of the product itself. These costs are allocated to products or services using various methods such as overhead rate allocation.

Examples of Indirect Costs in Manufacturing

Understanding indirect costs is crucial for accurate cost accounting. Here are five examples of indirect costs in a manufacturing business:

- Factory rent

- Factory utilities (electricity, gas, water)

- Factory supervisor salaries

- Depreciation of factory equipment

- Factory insurance

These costs are essential for production but are not directly attributable to a single product. Accurate allocation of these costs is critical for pricing decisions and profitability analysis.

Costing Methods

Cost accounting employs various methods to track and allocate costs, providing crucial insights for pricing strategies, performance evaluation, and decision-making. The choice of method depends heavily on the nature of the business and its products or services. Two prominent costing methods are job-order costing and process costing.

Job-Order Costing

Job-order costing is a method used to track costs for individual projects or jobs. This approach is particularly suitable for businesses that produce unique or customized products, such as construction companies, advertising agencies, or custom furniture makers. Each job is treated as a separate cost unit, and all direct costs and allocated indirect costs are assigned to that specific job.

The process of job-order costing involves several key steps:

- Identify the Job: Assign a unique identifier to each job or project.

- Track Direct Costs: Accurately record all direct materials used and direct labor hours spent on the job.

- Allocate Indirect Costs: Apply overhead costs (e.g., rent, utilities, factory supervision) to the job using a predetermined overhead rate. This rate is typically calculated by dividing estimated total overhead costs by an estimated allocation base (e.g., direct labor hours, machine hours).

- Calculate Total Job Cost: Sum the direct materials, direct labor, and allocated overhead costs to determine the total cost of the job.

- Compare to Budget: Analyze the actual cost against the budgeted cost to identify areas for improvement and cost control.

Example: A custom furniture maker receives an order for a unique dining table (Job #123). Direct materials costing $500 are used, and direct labor of 20 hours at $25/hour is incurred. The predetermined overhead rate is $10 per direct labor hour. The total cost of Job #123 is calculated as follows:

Direct Materials: $500

Direct Labor (20 hours x $25/hour): $500

Overhead (20 hours x $10/hour): $200

Total Job Cost: $1200

Process Costing

Process costing is used when similar products are mass-produced in a continuous process. This method is ideal for businesses like food processors, chemical manufacturers, or oil refineries. Costs are tracked for each stage of the production process, and then averaged across all units produced.

Process costing is particularly suitable for businesses with:

- High-volume production of homogenous products.

- Continuous production flow.

- Similar production processes for all units.

Businesses unsuitable for process costing would include those producing highly customized or unique items, where individual job costing is more appropriate.

Browse the implementation of The Role of Financial Accounting in Economic Policy Formulation in real-world situations to understand its applications.

Comparison of Job-Order and Process Costing

Job-order costing and process costing offer distinct advantages and disadvantages. Job-order costing provides detailed cost information for individual jobs, facilitating accurate pricing and profitability analysis. However, it can be more complex and time-consuming, especially for businesses with numerous small jobs. Process costing is simpler and more efficient for mass production, but it provides less detailed cost information for individual units.

| Feature | Job-Order Costing | Process Costing |

|---|---|---|

| Type of Product | Unique or customized | Homogenous, mass-produced |

| Cost Unit | Individual job or project | Unit of production (e.g., gallon, pound) |

| Cost Tracking | Tracks costs for each job | Tracks costs for each process or department |

| Cost Calculation | Direct costs + allocated overhead | Total costs / number of units |

| Applications | Construction, custom manufacturing, advertising | Food processing, chemical manufacturing, oil refining |

Cost-Volume-Profit (CVP) Analysis

Cost-Volume-Profit (CVP) analysis is a crucial management accounting tool that examines the relationship between three key factors: cost, volume, and profit. Understanding this relationship allows businesses to make informed decisions regarding pricing, production levels, and sales targets, ultimately maximizing profitability. This analysis relies on several key assumptions, including constant selling prices, constant variable costs per unit, and fixed costs remaining unchanged within a relevant range of activity.

Break-Even Analysis and its Significance

Break-even analysis is a fundamental component of CVP analysis. It determines the point where total revenue equals total costs, resulting in neither profit nor loss. This break-even point is significant because it provides a benchmark for evaluating the financial viability of a product or business. Knowing the break-even point allows businesses to assess the minimum sales volume required to cover all costs and begin generating profit. This information is invaluable in setting sales targets, pricing strategies, and evaluating the financial risk associated with new ventures or product lines.

Calculating the Break-Even Point

The break-even point can be calculated in both units and sales dollars. The formula for the break-even point in units is:

Break-Even Point (Units) = Fixed Costs / (Selling Price per Unit – Variable Cost per Unit)

For example, if a company has fixed costs of $100,000, a selling price of $50 per unit, and variable costs of $30 per unit, the break-even point in units would be: $100,000 / ($50 – $30) = 5,000 units.

The break-even point in sales dollars is calculated as:

Break-Even Point (Sales Dollars) = Fixed Costs / ((Selling Price per Unit – Variable Cost per Unit) / Selling Price per Unit) or alternatively: Fixed Costs / Contribution Margin Ratio

Using the same example, the contribution margin ratio is ($50 – $30) / $50 = 0.4 or 40%. Therefore, the break-even point in sales dollars is $100,000 / 0.4 = $250,000.

Impact of Changes on the Break-Even Point

Changes in selling price, variable cost, and fixed cost directly impact the break-even point. An increase in selling price or a decrease in variable costs will lower the break-even point, making it easier to achieve profitability. Conversely, an increase in fixed costs or variable costs will raise the break-even point, requiring higher sales volume to achieve profitability. For instance, a 10% increase in fixed costs would necessitate a corresponding increase in sales to maintain the same profit level. Similarly, a reduction in variable costs through improved efficiency would lower the break-even point, improving the company’s financial health.

CVP Graph

A CVP graph visually represents the relationship between cost, volume, and profit. The horizontal axis represents the volume of units sold, while the vertical axis represents both costs and revenue in monetary units. Three lines are plotted: a total revenue line (starting from the origin and sloping upwards), a total cost line (starting at the level of fixed costs and sloping upwards), and a profit/loss line. The point where the total revenue and total cost lines intersect represents the break-even point. For example, using the previous data, the total revenue line would start at zero and increase linearly with each unit sold. The total cost line would start at $100,000 (fixed costs) and increase linearly based on the variable cost per unit. The intersection of these two lines would be at 5,000 units, visually demonstrating the break-even point. The area between the total revenue and total cost lines after the break-even point represents profit, while the area before the intersection represents a loss.

Budgeting and Cost Control

Budgeting and cost control are crucial for the financial health of any organization. Effective budgeting provides a roadmap for achieving financial goals, while robust cost control mechanisms ensure resources are used efficiently and effectively, maximizing profitability and minimizing waste. This section will explore the key components of a master budget, the process of creating a flexible budget, various cost control methods, and a systematic approach to analyzing budget variances.

Master Budget Components

A master budget is a comprehensive financial plan encompassing all aspects of a business’s operations for a specific period. It integrates various individual budgets to provide a holistic view of expected revenues, expenses, and financial position. Key components typically include the sales budget (forecasting sales revenue), production budget (determining production levels needed to meet sales demand), direct materials budget (estimating the cost of raw materials), direct labor budget (projecting labor costs), manufacturing overhead budget (forecasting indirect manufacturing costs), selling and administrative expense budget (detailing operating expenses), capital expenditure budget (planning for investments in long-term assets), and the cash budget (projecting cash inflows and outflows). The master budget culminates in projected financial statements, including the budgeted income statement and balance sheet. These statements offer a critical evaluation of the organization’s anticipated financial performance.

Flexible Budget Creation

Unlike a static budget, a flexible budget adjusts to changes in activity levels. Creating a flexible budget involves several steps. First, identify the relevant cost drivers. These are factors that influence the costs incurred (e.g., production volume, sales revenue). Second, determine the variable and fixed cost components for each cost category. Variable costs change directly with activity levels, while fixed costs remain constant regardless of activity. Third, develop cost formulas that express the relationship between costs and the chosen cost drivers. For example, a cost formula for direct materials might be: Direct Materials Cost = $X per unit * Number of Units Produced. Fourth, prepare the flexible budget for different activity levels. This involves plugging various activity levels into the cost formulas to generate corresponding budget figures. This allows management to compare actual results against expected results at various levels of production or sales, providing a more accurate assessment of performance.

Cost Control Methods

Several methods exist for controlling costs. Standard costing, for instance, sets predetermined standards for materials, labor, and overhead, enabling comparisons between actual and standard costs to identify areas needing improvement. Budgetary control involves comparing actual results against budgeted figures, facilitating proactive corrective actions. Activity-based costing (ABC) assigns overhead costs based on the activities that consume resources, providing a more accurate cost allocation for decision-making. Value engineering focuses on identifying cost reductions without compromising product quality or functionality. Benchmarking compares a company’s performance against industry best practices to identify areas for improvement. Lean manufacturing aims to eliminate waste throughout the production process, improving efficiency and reducing costs. These methods can be applied in diverse settings, from manufacturing plants to service industries, depending on the specific context and objectives.

Budget Variance Analysis and Corrective Actions

Analyzing budget variances involves a systematic comparison of actual results against budgeted figures. This analysis helps pinpoint areas where performance deviated from expectations. The process typically involves calculating the variance (difference between actual and budgeted figures), determining the variance’s materiality (significance), and identifying the root causes of the variance. For example, a significant unfavorable variance in direct materials cost could be due to price increases, inefficient material usage, or quality issues. Once the causes are identified, corrective actions can be implemented. These might involve negotiating better prices with suppliers, improving production processes to reduce waste, or addressing quality control problems. Regular monitoring and analysis of budget variances are critical for effective cost control and ensuring the organization stays on track to achieve its financial goals. This continuous feedback loop allows for adjustments to the budget and operational strategies as needed.

Standard Costing

Standard costing is a powerful technique used in cost accounting to establish predetermined costs for products or services. It involves setting benchmark figures for materials, labor, and overhead, which are then compared to actual costs to identify variances and pinpoint areas for improvement. This proactive approach allows businesses to monitor performance, enhance efficiency, and make informed decisions.

Standard costing offers several key benefits. By providing a benchmark against which actual costs can be measured, it facilitates efficient cost control and variance analysis. This allows for early detection of inefficiencies and facilitates prompt corrective action. Furthermore, it aids in pricing decisions, budgeting, and performance evaluation, providing a clearer picture of profitability and operational effectiveness. Finally, it simplifies cost accounting processes, streamlining data collection and analysis.

Material, Labor, and Overhead Variances

Calculating variances involves comparing the standard costs to the actual costs incurred. Let’s examine the calculation of each type of variance: material, labor, and overhead.

Material variances are differences between the standard cost of materials used and the actual cost of materials used. These variances can be further broken down into price and usage variances. The price variance reflects the difference between the actual price paid for materials and the standard price, while the usage variance reflects the difference between the actual quantity of materials used and the standard quantity allowed for production.

Labor variances are differences between the standard labor cost and the actual labor cost. Similar to material variances, these can be separated into rate and efficiency variances. The rate variance reflects differences in the actual hourly wage rate paid compared to the standard rate, while the efficiency variance reflects differences in the actual labor hours used compared to the standard hours allowed for production.

Overhead variances are differences between the standard overhead cost and the actual overhead cost. These variances are often more complex to calculate and analyze due to the nature of overhead costs. They can be further broken down into various components, such as variable and fixed overhead variances, and further subdivided based on factors such as spending, efficiency, and volume.

Variance Analysis and Efficiency Improvement

Variance analysis is crucial for improving operational efficiency. By analyzing the individual variances (material price, material usage, labor rate, labor efficiency, variable overhead spending, variable overhead efficiency, fixed overhead budget, and fixed overhead volume), management can identify the root causes of inefficiencies and implement corrective actions. For example, a significant unfavorable material price variance might indicate a need to renegotiate contracts with suppliers, while a high unfavorable labor efficiency variance could signal a need for improved training or process optimization. The analysis shouldn’t just identify the problem; it should also guide the solutions.

Types of Variances and Their Formulas

Understanding the different types of variances and their calculations is critical for effective variance analysis. The following table summarizes the key variances and their formulas:

| Variance Type | Formula | |

|---|---|---|

| Material Price Variance | (Actual Price – Standard Price) x Actual Quantity | |

| Material Usage Variance | (Actual Quantity – Standard Quantity) x Standard Price | |

| Labor Rate Variance | (Actual Rate – Standard Rate) x Actual Hours | |

| Labor Efficiency Variance | (Actual Hours – Standard Hours) x Standard Rate | |

| Variable Overhead Spending Variance | (Actual Variable Overhead – Budgeted Variable Overhead) | |

| Variable Overhead Efficiency Variance | (Actual Hours – Standard Hours) x Standard Variable Overhead Rate | |

| Fixed Overhead Budget Variance | (Actual Fixed Overhead – Budgeted Fixed Overhead) | |

| Fixed Overhead Volume Variance | (Budgeted Fixed Overhead – Applied Fixed Overhead) |

Last Recap

Mastering the basics of cost accounting empowers businesses to make data-driven decisions, optimize resource allocation, and ultimately enhance profitability. By understanding cost behavior, employing appropriate costing methods, and implementing effective budgeting and control strategies, organizations can gain valuable insights into their operational efficiency and financial performance. This foundational knowledge serves as a springboard for more advanced cost management techniques, enabling businesses to thrive in a competitive landscape.

Commonly Asked Questions

What is the difference between cost accounting and financial accounting?

Cost accounting focuses on internal decision-making, tracking costs for specific products or services. Financial accounting focuses on external reporting, creating financial statements for stakeholders.

How is cost accounting used in pricing decisions?

Cost accounting helps determine the cost of goods sold, allowing businesses to set prices that cover costs and ensure a desired profit margin.

What are some common errors in cost accounting?

Common errors include inaccurate cost allocation, neglecting opportunity costs, and failing to account for all relevant costs.

Can small businesses benefit from cost accounting?

Absolutely. Even small businesses can benefit from basic cost accounting to track expenses, price products effectively, and make informed decisions about resource allocation.